Material Selection for Pharmaceutical Machinery under Different Corrosion Conditions

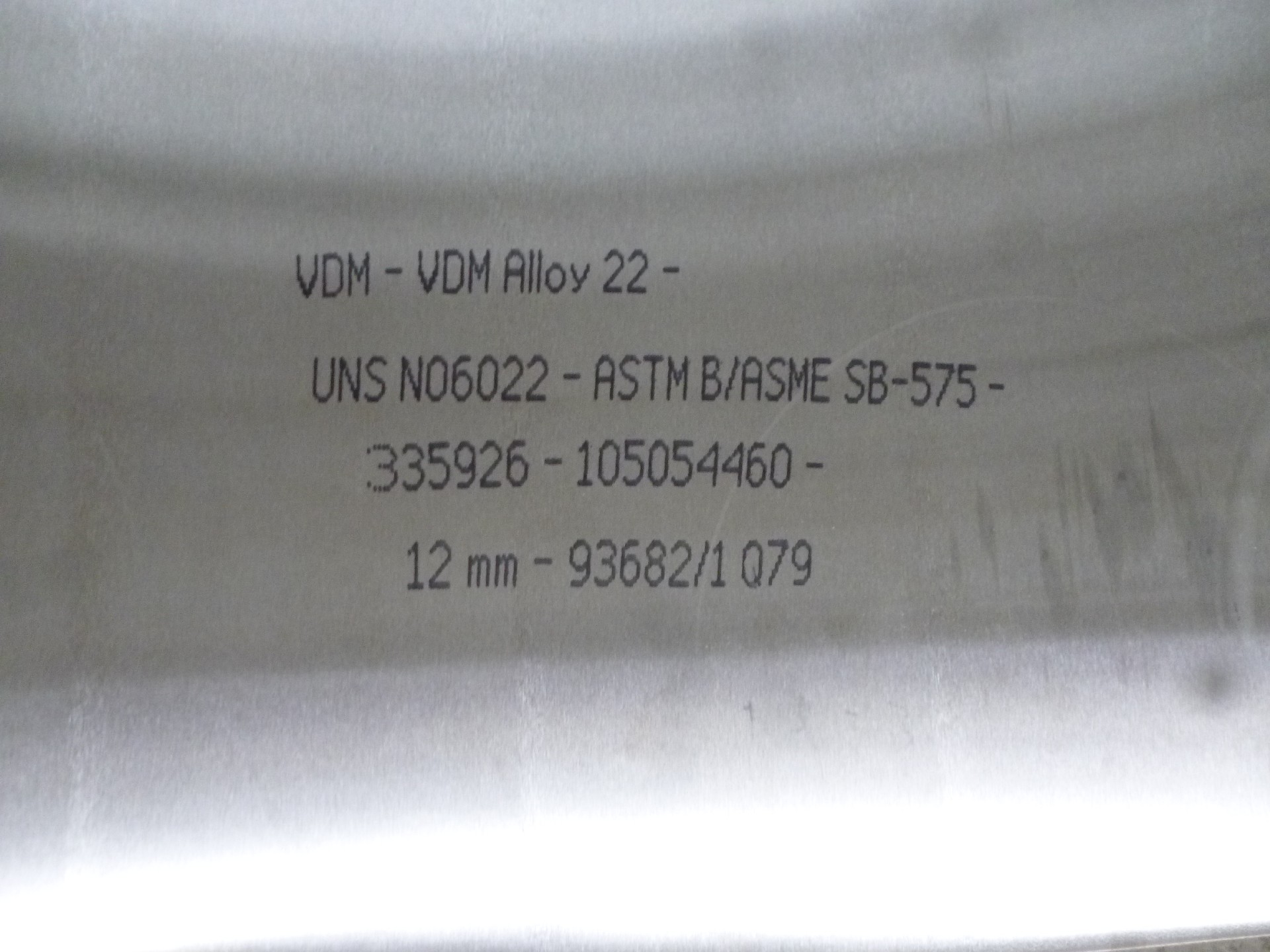

Core Principle for Strongly Corrosive Pharmaceutical Machinery: Select materials based on corrosion intensity classification, with key focus on avoiding metal leaching and intergranular corrosion risks. I. Extreme Strong Corrosion Scenarios (Compatible with concentrated acids / Chloride-containing / Fluoride-containing / Alternating multiple media) Hastelloy C-22 (Hastelloy Alloy): Applications: Reaction vessels for chloride-containing APIs, equipment contacting hydrofluoric acid/concentrated nitric acid, core components in CIP systems with acid-base alternation (e.g., filling machine valve cores, heat exchanger tube bundles). Advantages: PREN ≈ 70 (top-tier resistance to pitting/crevice corrosion), low carbon content prevents intergranular corrosion, requires no post-weld treatment, fully complies with GMP requirements for no leaching. Hastelloy C-276 (Hastelloy Alloy): Applications: Synthesis equipment for high-sulfur APIs, concentrated hydrochloric acid reaction tanks; serves as a cost-effective alternative to C-22 (10%-15% lower cost). Advantages: Corrosion resistance close to C-22, suitable for most strongly corrosive media, slightly inferior to C-22 only in extreme high-chloride conditions. Titanium and Titanium Alloys (TA2/TC4): Applications: High-temperature organic acid extraction tanks (e.g., TCM concentration equipment), reactors where steam sterilization (134°C) and corrosive media coexist. Advantages: Excellent high-temperature corrosion resistance, superb biocompatibility (no heavy metal leaching), suitable for high-end sterile preparation scenarios. II. Moderate Strong Corrosion Scenarios (Compatible with dilute acids / Organic solvents / High salinity) 316L Stainless Steel (Low-Carbon Grade): Applications: Reaction vessels for dilute acids/bases, pipelines for ethanol/acetone solvent transfer, vaccine fermenters (non-extreme corrosion). Advantages: PREN ≈ 38, low carbon prevents intergranular corrosion, surface can be polished to Ra ≤ 0.8µm (GMP compliant), cost is only 1/8 - 1/10 of Hastelloy alloys. Duplex Stainless Steel (2205): Applications: Storage tanks for high-salinity biological fermentation broths, seawater-cooled heat exchangers (pharmaceutical cooling water systems). Advantages: Better pitting resistance than 316L (PREN ≈ 45), high strength, suitable for combined conditions of high salinity and mild corrosion. III. Special Strong Corrosion Scenarios (Reducing environments / High-purity media) Hastelloy B-2 (Hastelloy Alloy): Applications: Reaction equipment for strong reducing acids like concentrated hydrochloric acid, formic acid (316L/titanium alloys are prone to hydrogen-induced corrosion in these media). Advantages: Top-tier corrosion resistance to reducing media, no risk of hydrogen embrittlement. Quartz / High Borosilicate Glass: Applications: High-purity drug solution preparation tanks, laboratory-grade chromatography columns (strong corrosion + ultra-high purity requirements). Advantages: Completely inert, no leaching, suitable for high-end formulations. Disadvantages: Brittle, low impact resistance, limited to small equipment/components. IV. Core Material Selection Principles Media Priority: Select C-22 for chloride/fluoride-containing media, B-2 for reducing acids, titanium alloys for high-temperature organic acids. Avoid "forcing standard stainless steel to handle strong corrosion". GMP Compliance: Product contact materials must be non-adsorptive and non-leaching. Prioritize polishable alloys (Hastelloy/316L) or inert plastics. Cost Control: Use Hastelloy/titanium alloys for core contact parts, 316L/2205 for non-contact structural parts, and 304 for casings/brackets (external corrosion protection). Manufacturing Suitability: For welded components, prioritize low-carbon alloys (C-22/316L) to avoid post-weld intergranular corrosion. Avoid using plastic components in high-temperature conditions.

Core: Opt for "All-round Corrosion-Resistant Alloys", replacing standard stainless steels to avoid premature failure.

Balance corrosion resistance and cost, prioritize "Upgraded Stainless Steels + Inert Plastics".

Select specialized materials targeted to the specific challenge, avoid "mismatch failure".