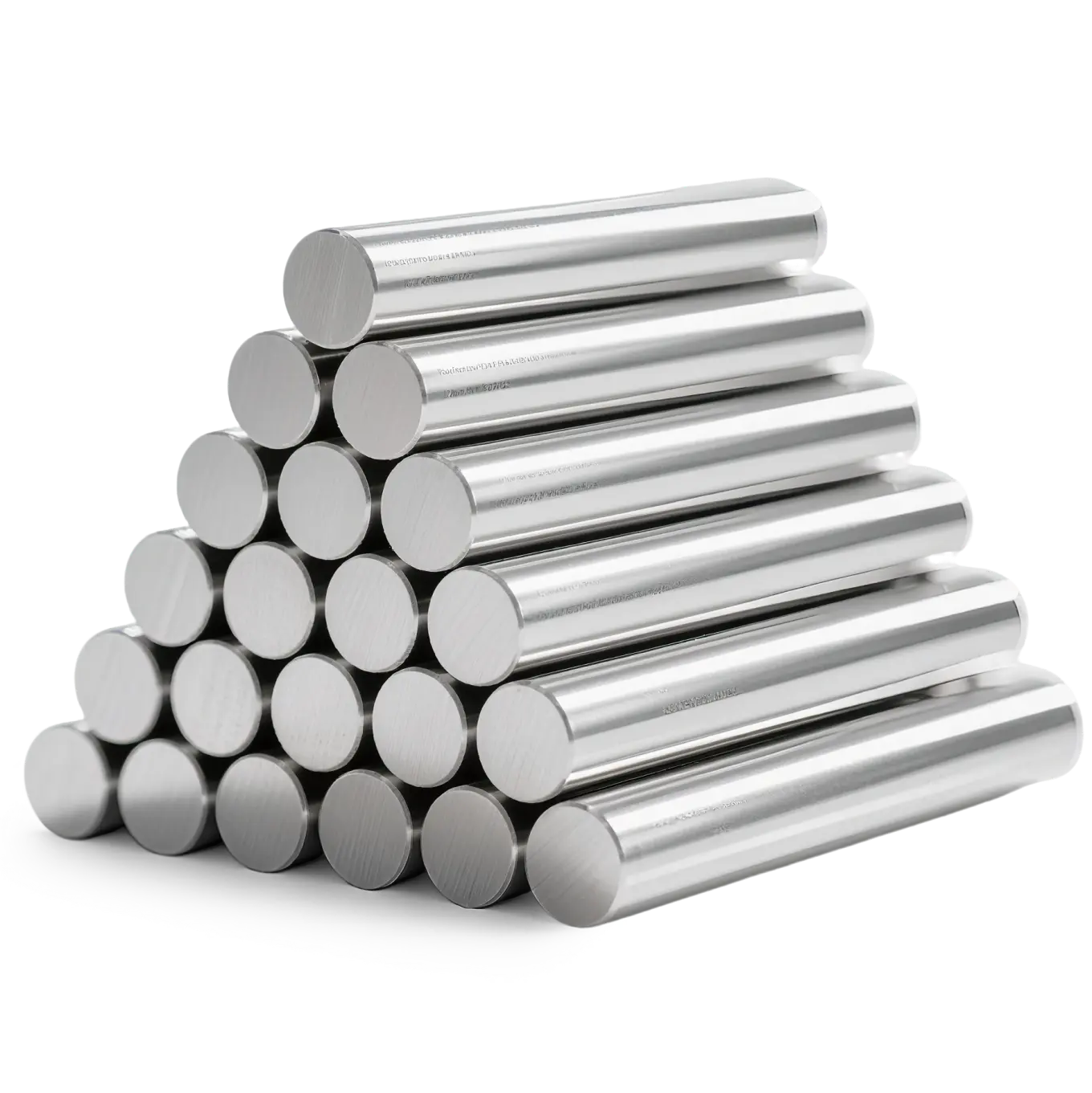

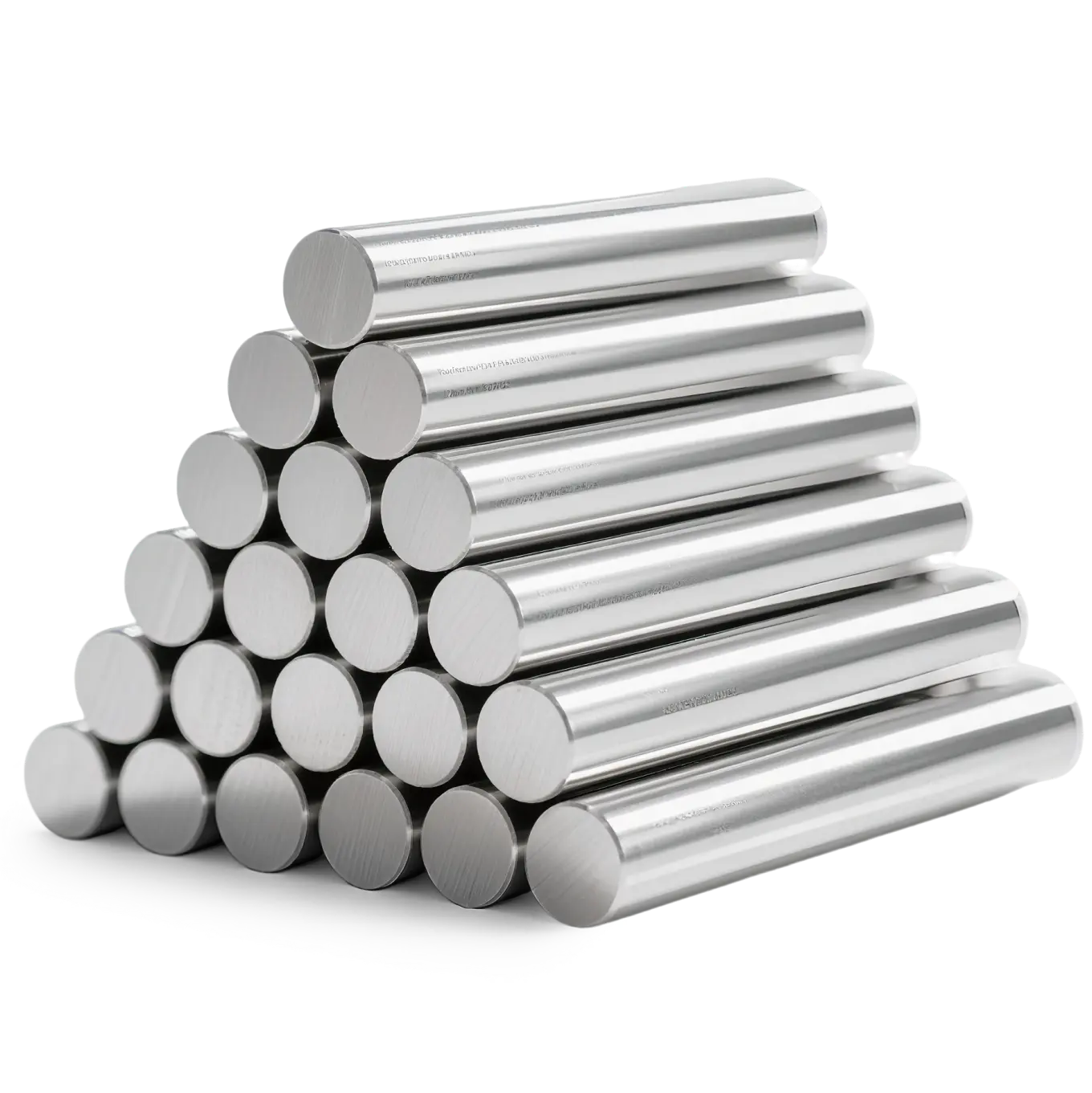

Our materials jointly fend off corrosion from high-altitude moisture, fuel residues, and extreme atmospheric conditions, endure intense temperatures and extreme pressure changes, fit both core operations and routine equipment needs, ensuring safe flight operations, minimal maintenance demands, and long-lasting reliability for commercial jets, military aircraft, and spacecraft.