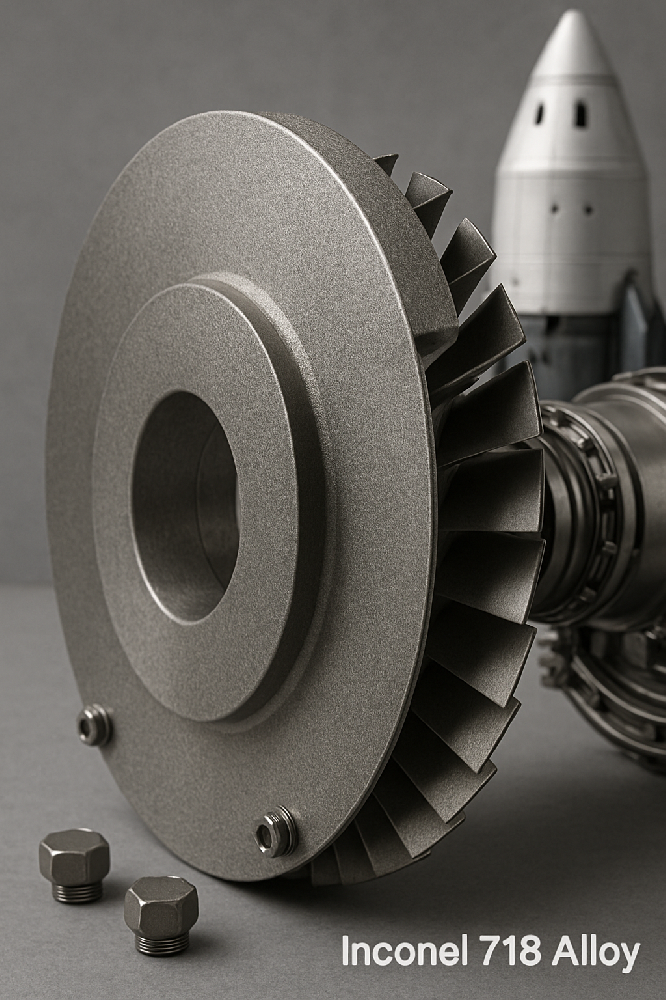

Inconel718 Alloy

Inconel718 Alloy

Basic Information

Name: Inconel718, also known as Alloy 718

Similar Designations:

GH4169, GH169 (China)

NC19FeNb (France)

NiCr19Fe19Nb5, Mo3 (Germany)

NA51 (UK)

UNS NO7718 (USA)

NiCr19Nb5Mo3 (ISO)

Chemical Composition

Nickel (Ni): 50%-55%, serving as the matrix of the alloy, providing excellent high-temperature toughness and oxidation resistance.

Chromium (Cr): 17%-21%, forms a dense chromium oxide layer on the surface, enhancing high-temperature oxidation resistance.

Iron (Fe): Used to optimize cost and overall performance.

Niobium (Nb): 4.75%-5.5%, combines with titanium to form the γ'' strengthening phase, which significantly improves strength through age-hardening mechanisms.

Molybdenum (Mo): 2.8%-3.3%, enhances creep resistance and corrosion resistance in aggressive media.

Other Elements: Aluminum (Al, 0.2%-0.8%), titanium (Ti, 0.65%-1.15%), and other trace elements refine grain structure and strengthen phase formation.

Physical Properties

Density: 8.24 g/cm³

Melting Temperature Range: 1260-1320°C

Coefficient of Thermal Expansion: ~13.3×10⁻⁶/°C (average from room temperature to 1000°C).

Thermal Conductivity: ~11.4 W/(m·K) at room temperature, increasing with temperature.

Mechanical Properties

High Strength:

Room temperature: Tensile strength up to 1370 MPa, yield strength of 1030 MPa.

At 650°C: Tensile strength remains at 1100 MPa, yield strength at 890 MPa.

Good Toughness:

Elongation of 12% at room temperature, increasing to 15% at high temperatures.

Exhibits excellent impact resistance and deformation tolerance.

Fatigue Resistance: Resists crack initiation and propagation under cyclic loading, making it suitable for components subjected to repeated stress.

Creep Resistance: Maintains dimensional stability under prolonged high-temperature and high-stress conditions.

Processing & Heat Treatment

Machinability:

Can be forged, rolled, and machined, but work-hardening requires appropriate tooling and techniques.

Heat Treatment:

Solution Treatment: Produces a uniform austenitic structure, improving workability.

Precipitation Hardening (Aging): Enhances hardness and strength by precipitating strengthening phases.

Corrosion Resistance

Pitting & Crevice Corrosion Resistance: Highly resistant to chloride-containing environments.

Stress Corrosion Cracking (SCC) Resistance: Performs well under tensile stress in corrosive media.

Oxidation Resistance: High chromium content forms a protective oxide layer, preventing further degradation in high-temperature oxidizing environments.

Applications

Aerospace: Turbine disks, blades, fasteners in jet engines; structural and propulsion components in spacecraft.

Energy Sector: Gas turbines, liquid-fueled rockets, cryogenic and nuclear engineering components (e.g., reactor structures, piping, and valves).