Inconel 625LCF Introduction

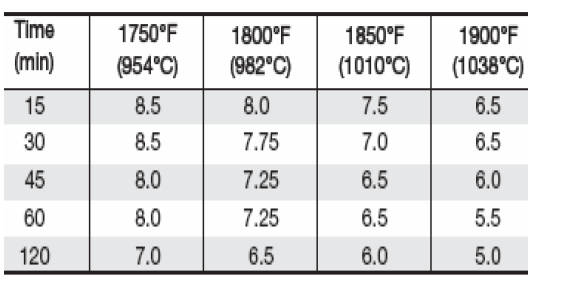

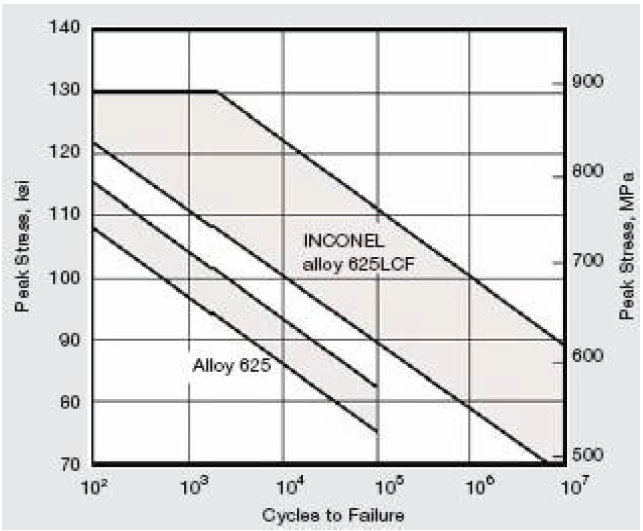

Inconel 625LCF Introduction Inconel 625LCF is a nickel-based alloy specifically optimized for low-cycle fatigue (LCF) and high-temperature environments. Its performance characteristics and applications are as follows: Base Composition: Similar to standard Inconel 625 (Ni ≥ 58%, Cr 20-23%, Mo 8-10%, Nb 3.15-4.15%), but has strict control over C, Si, and N content (C ≤ 0.03%, Si ≤ 0.5%, N ≤ 0.015%) through vacuum induction melting (VIM). Grain Refinement: Average grain size of ASTM No.5 (0.064 mm) or finer, which significantly enhances fatigue and thermal fatigue resistance. Room Temperature Performance: Tensile strength ≥ 830 MPa, yield strength ≥ 415 MPa, elongation ≥ 30%, Brinell hardness ≤ 220 HB. High-Temperature Performance: Maintains high strength at 650°C, with ASME allowable stress approximately 4 ksi (27.6 MPa) higher than standard 625, suitable for long-term service below 700°C. Fatigue Performance: Superior low-cycle fatigue life compared to traditional 625, particularly outstanding in high-stress bellows testing. Inherits the excellent corrosion resistance of Inconel 625, resisting chlorides, organic acids, salt solutions, and high-temperature oxidation environments. Certified by NACE MR0175 for sour gas service. Can be processed via cold/hot rolling and forging. Exhibits good weldability with no post-weld cracking risk, making it suitable for manufacturing complex structural components. Engine Components: Combustion chambers, transition ducts, exhaust systems, and thrust reversers, leveraging its high-temperature strength and fatigue resistance. Bellows and Expansion Joints: High-stress cyclic scenarios (e.g., aircraft bleed air ducts), with significantly longer lifespan than traditional 625. Nuclear and Chemical Industries: Pressure vessels, heat exchangers, and expansion joints, which are resistant to high temperatures, pressure, and corrosive media. Automotive and Racing: Flexible exhaust connectors, that are optimized for vibration fatigue resistance. Ship exhaust systems and seawater treatment equipment, that are resistant to salt spray corrosion and dynamic loads. Oil and gas wellhead equipment, deep-sea risers, which are capable of withstanding high pressure and temperature fluctuations. Manufacturing Process: Utilizes VIM melting + precision thermomechanical processing to ensure uniform composition and grain refinement, complying with SAE AMS 5879 standards. Performance Comparison: Traditional 625 cannot meet AMS 5879 fatigue requirements, while 625LCF exhibits significant lifespan advantages in high-temperature cycling. Precipitate Control: Long-term service at 593-650°C requires attention to γ'' and M23C6 carbide precipitation effects, but composition optimization has greatly mitigated this issue. Aircraft Engines: A certain model's combustion chamber transition section using 625LCF achieved a 50-fold increase in fatigue life compared to traditional materials, reducing maintenance frequency. Racing Exhaust Systems: An F1 team adopted 625LCF bellows, which showed no cracks after 100,000 vibration cycles, whereas traditional materials failed after only 1,000 cycles. Laser powder bed fusion (LPBF)-fabricated 625LCF-based composites (e.g., with TiB2 additives) demonstrated a 68% increase in tensile strength at 800°C and a 15-fold extension in creep rupture time, opening new possibilities for ultra-high-temperature applications.I. Core Performance

1. Chemical Composition and Microstructure

2. Mechanical Properties

3. Corrosion Resistance

4. Processing and Welding

II. Key Application Fields

1. Aerospace

2. Energy and Industry

3. Marine Engineering

4. Extreme Environments

III. Technical Advantages and Standards

IV. Representative Cases

V. Latest Developments